|

<< Click to Display Table of Contents >> Design Tab |

|

|

<< Click to Display Table of Contents >> Design Tab |

|

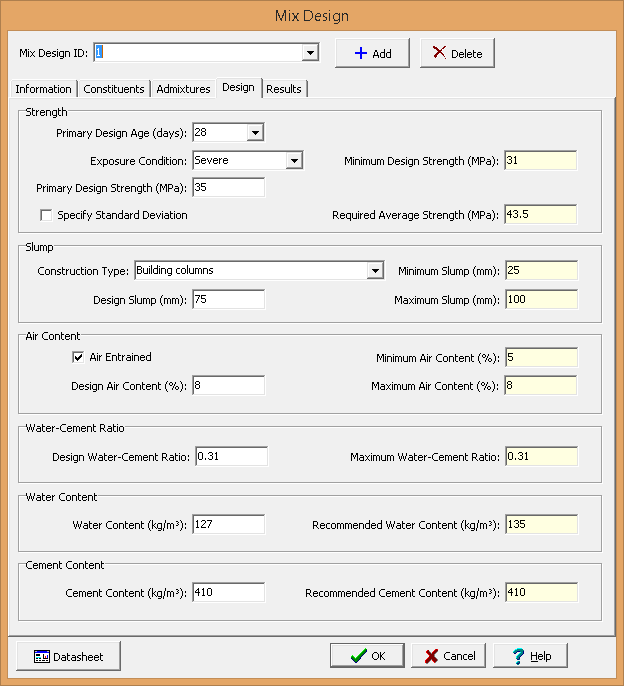

This tab is used to specify the design criteria for the mix.

It is recommended that the design criteria be specified in the order they appear in the tab. The following can be specified on this tab:

Strength

Primary Design Age: This is used to select the primary design age of the concrete. It is typically 28 days. The design ages can be selected from a list of predefined concrete ages.

Exposure Condition: This is the exposure condition of the concrete. It can be mild, moderate, severe, or very severe.

Minimum Design Strength: This is the minimum recommended design strength based on the selected exposure condition. It is determined from a list of predefined minimum strengths.

Primary Design Strength: This is used to specify the primary design strength for the concrete. It should be greater than the minimum design strength.

Specify Standard Deviation: Check this box to specify the standard deviation to be used to determine the required average strength. If the box is checked the standard deviation can be entered to the right of the box.

Required Average Strength: The required average strength should be greater than the design strength to allow for variations in materials, mixing, placement, curing, etc. of the concrete. If the standard deviation is specified it is used to determine the required average strength. If the standard deviation is not specified then the program will determine the required average strength based on the primary design strength.

Slump

Construction Type: This is the type of construction where the concrete will be used. It can be selected from a list of predefined construction types and recommended slumps.

Minimum Slump: This is the minimum recommended slump that is associated with the construction type. It is automatically filled in by the program.

Maximum Slump: This is the maximum recommended slump that is associated with the construction type. It is automatically filled in by the program.

Design Slump: This is used to specify the design slump. It should be between the minimum and maximum recommended slump. The design slump is used in determining the mixing water and target air content requirements. It is also used to determine the minimum and maximum slump for batch requirements.

Air Content

Air Entrained: Check this box if the concrete is to be air entrained.

Minimum Air Content: This is the minimum recommended air content based on the exposure and maximum aggregate size. It is 1% less than the amount specified in the predefined list of target air contents.

Maximum Air Content: This is the maximum recommended air content based on the exposure and maximum aggregate size. It is 2% higher than the amount specified in the predefined list of target air contents.

Design Air Content: This is used to specify the design air content. It should be between the minimum and maximum recommended air contents. The design air content is also used in determining the proportions of constituents.

Water-Cement Ratio

Design Water-Cement Ratio: This is used to specify the design water-cementitious material ratio. It should be less than the recommended maximum water-cement ratio.

Maximum Water-Cement Ratio: This is the recommended maximum water-cementitious material ratio required to meet exposure conditions and required strength. It is interpolated from a list of predefined maximum water-cement rations.

Water Content

Water Content: This is used to specify the design water content.

Recommended Water Content: This is the recommended water content. The recommended water content is based on the maximum aggregate size, slump, air-entrainment, and water reducing admixtures. It is selected from a list of predefined mixing water requirements corrected for any water reducing admixtures.

Cement Content

Cement Content: This is used to specify the design cement content.

Recommended Cement Content: This is the recommended cement content. It is obtained by dividing the design water content by the design water-cement ratio.