When it comes to site characterization, your monitoring well is only as reliable as the materials surrounding it. Choosing the right filter pack and grout isn’t just about “filling the hole”—it’s about ensuring hydraulic connectivity while preventing cross-contamination.

Filter Pack

1. Filter Pack Material Selection

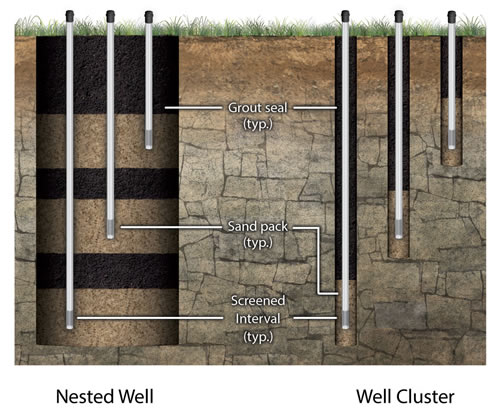

The filter pack (or sand pack) acts as a mechanical filter to keep fine formation particles out of your well screen while allowing groundwater to flow freely.

- Material: Use clean, well-rounded, chemically inert silica sand. Avoid limestone or calcareous materials, as they can alter the pH and chemistry of your samples.

- Sizing: The grain size must be matched to your well screen slot size. For example, 20/40 grade silica sand is typically paired with a 0.010-inch (#10) slot screen.

- Standard Compliance: Follow ASTM D5092 guidelines for design and installation to ensure representative sampling.

2. Filter Pack Required

For a typical 2-inch (2.375″ OD) PVC monitoring well, the amount of filter pack sand required depends on the diameter of the borehole created by your drilling method (e.g., hollow stem auger or sonic).

The table below provides the volume per linear foot of the annular space (the gap between the casing and the borehole wall) where the sand is placed.

Filter Pack Volume for 2-inch Monitoring Well

Calculated for 2.375″ OD Casing

| Borehole Size (in) | Volume per Foot ( | Volume per Foot (Gallons) | Approx. Bags per 10 ft* |

|---|---|---|---|

| 4.0 | 0.056 | 0.42 | 1.2 |

| 6.0 | 0.166 | 1.24 | 3.5 |

| 8.0 | 0.318 | 2.38 | 6.4 |

| 10.0 | 0.512 | 3.83 | 10.3 |

*Based on standard 50-lb bags of silica sand, which typically have a volume of ~0.5

Key Planning Factors

- Total Height: Remember to calculate for the entire “sand column,” which includes the length of the screen plus at least 2 feet above the top of the screen to prevent grout infiltration.

- The “Washout” Factor: In unstable formations like loose sand or gravel, the borehole may be wider than the drill bit. It is standard practice to add a 10%–20% contingency to your order.

- Centering: Always use centralizers in boreholes larger than 4 inches to ensure the filter pack is evenly distributed around the screen, preventing “thin spots” that could allow sediment into the well.

Seal and Grout

1. Grout and Sealing Materials

Grout prevents surface water or fluids from different aquifers from migrating down the well’s annular space.

- Bentonite Seal: A transition seal of hydrated bentonite chips or pellets (at least 2 feet thick) must be placed directly above the filter pack to prevent grout from infiltrating the screen area.

- Main Grout: The remaining annulus is usually filled with a bentonite-cement slurry or neat cement grout. Use Type 1 Portland Cement mixed at a ratio of approximately 6 gallons of water per 94-lb bag to achieve a density of 15 lbs/gal.

- Caution: Avoid using cement near the screen in sensitive chemical monitoring, as the high heat of hydration can damage PVC and skew chemical results.

2. Seal and Grout Required

To complete your well design, you’ll need both the bentonite transition seal (placed immediately above the filter pack) and the main annular grout (extending to the surface).

For a standard 2-inch (2.375″ OD) monitoring well, use the table below to estimate material needs per linear foot of the borehole.

Grout and Seal Material Estimates (2″ Well)

Calculations based on 2.375″ OD Casing

| Borehole Size | Vol. per Foot ( | Bentonite Chips (Bags/10 ft)* | Grout Slurry (Gal/10 ft)** |

|---|---|---|---|

| 4.0 inch | 0.056 | 0.8 | 4.2 |

| 6.0 inch | 0.166 | 2.4 | 12.4 |

| 8.0 inch | 0.318 | 4.5 | 23.8 |

| 10.0 inch | 0.512 | 7.3 | 38.3 |

*Based on standard 50-lb bags of bentonite chips (approx. 0.7 cubed 𝑓𝑡 per bag).

**Based on US liquid gallons of mixed slurry.

Critical Application Guidelines

- The Bentonite Seal: Most regulations require a minimum 2-foot thick seal of hydrated bentonite pellets or chips above the filter pack. If you are working in a 6-inch borehole, you will need roughly half a bag of chips for this 2-foot interval.

- Grout Mix Ratio: For a standard neat cement grout, mix one 94-lb bag of Type 1 Portland Cement with no more than 6 gallons of clean water. This produces roughly 1.1

of slurry.

- Placement Method: Always use a tremie pipe to pump grout from the bottom up. This ensures the grout displaces any standing water or drilling fluids and prevents “bridging” (air pockets) that could compromise the seal.

- Hydration Time: Allow the bentonite seal to hydrate for at least 30–60 minutes before pumping the cement grout to prevent the heavy grout from sinking into the filter pack.